Customer Report

IMD Preform Factory Concept 4.0 – put into practice

IMD Ltd. offers preform manufacturers a flexible factory concept with inline monitoring and 100% offline inspection systems that can be easily integrated into existing production lines or entire production halls. The monitoring systems is claimed to ensure reliability on the entire production line via a portal that can be viewed from anywhere at any time. Now the efficiency of the IMDvista factory concept has been put into practice, for example at Acsur S.A. in Argentina, where they use the system for one and a half years now. What has been achieved so far?

«In recent years, we have continuously pushed forward the development of the IMDvista Preform Factory Concept 4.0 together with customers and our engineers. We are not only concerned with product testing, but with the entire production process. Now the efficiency has been put into practice, for example at Acsur S.A. in Tierra de Fuego in Argentina.»

George Kobel, Area Sales Manager, IMD

Like many other preform manufacturers, Acsur S.A. is experiencing an increase in production error rates, as more and more recycled material and UV blockers are processed and process problems such as black spots, color deviations, crystallisation and other errors in the production process occur and sometimes disappear again. Acsur S.A. has been manufacturing preforms and HDPE lids for the beverage, edible oil and detergent industries since 2002. They have nine production lines and a laboratory for quality control of the manufactured products. They use an Integrated Quality Management System (SGCI) supported by ISO 9001, FSSC 22000, ISO 14001 certifications.

IMDvista Factory Concept 4.0 for Acsur S.A. – three steps for higher preform Quality

Acsur’s existing production lines with several moulds and machines were upgraded in 2017 with the IMDvista Preform Factory Concept 4.0. The goal was to increase productivity and quality, and to learn more about sources of error in the production process in order to reduce or eliminate them. IMD Ltd. therefore implemented at Acsur S.A. a combination of:

- Online monitoring of the entire production process and

- Offline inspection of individual preforms if necessary (at high speed) and

- A portal for all data, for the evaluation and processing of data from the entire process.

First step: constant monitoring inline

As it is of high importance to have the production chain under control the first step of the concept is constant monitoring inline of the production, so as to avoid scrap production over a long period. An IMDvista PECO LUX system for inline monitoring of PET preforms has been integrated into each of the eight existing preform injection-moulding production lines.

IMDvista PECO LUX

- Process monitoring shot by shot

- Main performance quality drifts and color variations can be monitored in a continuous mode.

- Easy integration into any production system

- Requires no additional floor space

- No preform orientation needed

- High speed inspection camera – speed according your production line speed.

- Inspects a great variety of preform formats with a single set-up

- IMDvista V5 software, based on self-learn functions (AI)

Monitoring of the whole production process

Monitoring the process in the Acsur plant is not only a monitoring of the product itself (preforms), but it is a monitoring of the whole production process, beginning with the resin (in mixed raw material) and ending with the finished preform. By examining these processes, the Acsur management was able to draw a conclusion over the quality of their raw material. On the resin – for example contamination and foreign particles inside the product – as well as of the master batch (colour drifts during the production). Going a step further to the storage room, whether humidity or dust is contaminating the resin while in storage.

In the next step, the preform provides information on the process inside the machine. The operator is now able to conclude if the machine has a temperature or water and cooling problem (burn- /watermarks). If the tool/ mould – or injection process has a problem, it can be seen in the finished preform, because of the short shot trend analyser software or because of evidence of long gates.

Step two: Offline post inspection at high speed

The offline post inspection at high speed is carried out with the IMDvista PECO V3 with efficiency and precision. Only selected octabin boxes are inspected by IMDvista PECO V3 to make sure in the case of problems that only the bad preforms are sorted out while the good ones are used and sold. This factor guarantees Acsur S.A. a smooth production and quality management.

The IMDvista PECO V3 can be used inline or offline. It is a compact preform inspection system. The preforms are kept in one straight line, no bends, no corners etc.

IMDvista PECO V3

- Easy and fast product change (no mechanical size parts)

- Whole line easy to access (floor level)

- Cavity detection

- Conveyor belts only (no star wheels)

- Integrated bad part bin (half octabin on pallet)

- Bad and good part boxes easy accessable

- Box filling directly after conveyor

- Taking up less than 7sqm including the sorter

- High output speed of up to 90’000 p/h

Step three: One portal for all data – a network solution

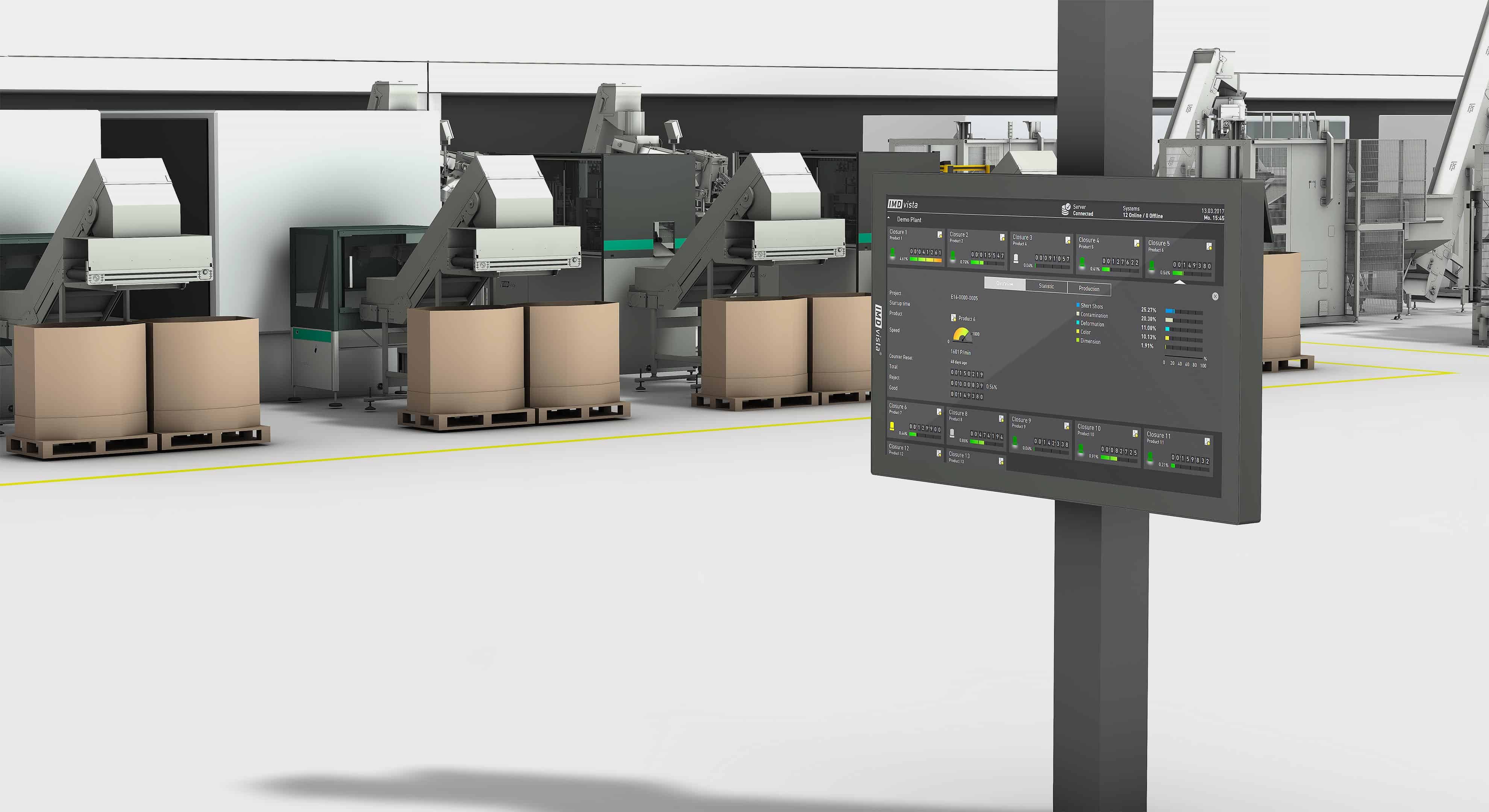

Using these values, the final piece of the puzzle for the Portal (data for software data based systems) can generate all these data to a single control center. The IMDvista PORTAL with a large touch screen connects all IMDvista vision systems and provides a complete overview of production, system setup, inspection and statistical data. Deviations and alarms are easy to understand and analyse. Further, immediate corrective actions can be taken directly on the systems. The navigation is intuitive and the system easy to use.

All the data generated during the process, the Acsur plant is now able to use in closed loop circuits, reports, statistic, time and date and other relevant information.

The Peco Lux Monitoring system is intended to provide Acsur with all the essential data they need to guarantee a precise production process without wasting time and energy on cost consuming post inspection of hours of production of preforms.

IMDvista PORTAL

Data for closed loop control and Industry 4.0:

- SPC for trend analysis

- Production and quality monitoring

- Remote access to vision systems

- Preventive action for high efficiency via the IMDvista Portal

«The IMDvista systems offer versatility and incorporation of new technologies for in-line and off-line product control. The in-line IMD equipment allows an automated configuration of the products to be produced, a high level of control as they take a significant percentage of parts and analyze them against defined quality parameters. The off-line equipment allows from small preforms up to the weight of the drum to carry out the 100% control of the pieces passed through the equipment, having a high performance at classification level since this equipment separates the pieces indicated as out of specification».

Ricardo Berger, Quality Manager, Acsur S.A.

Since the installation of these systems, the two companies Acsur S.A. and IMD Ltd. have been exchanging experiences and are continuously optimizing the systems. The technical and commercial support is provided remotely, or personally directly at the factory, by the globally available service technicians.