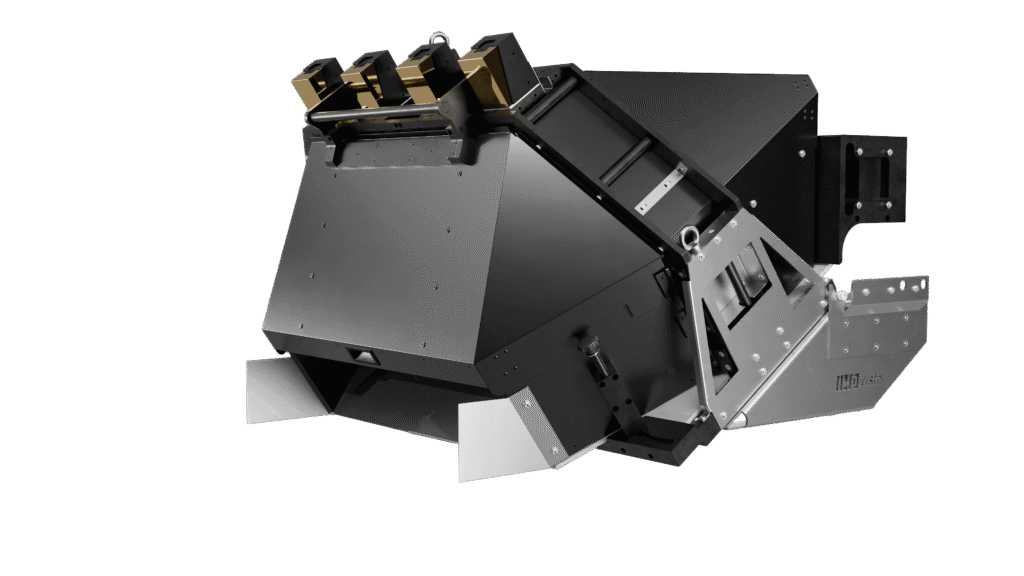

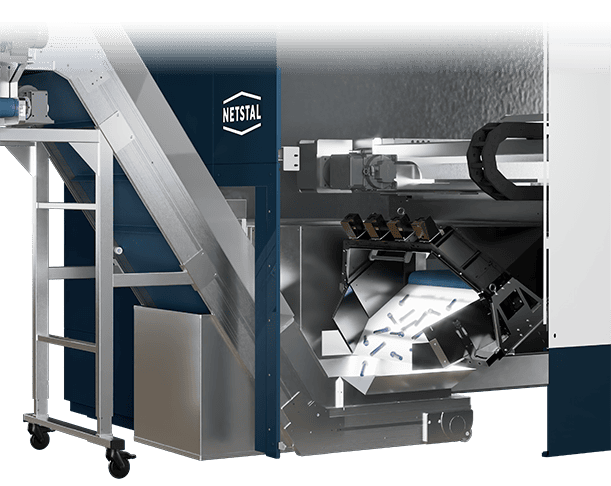

Martin Gerber, IMD (CSO): “Many customers operate 5, 10, or up to 20 PECO LUX systems across their facilities making calibration and validation an incredible valuable feature in order to guarantee identical production quality. The new-gen PECO LUX V3 is claimed to offer exactly this new capability”.

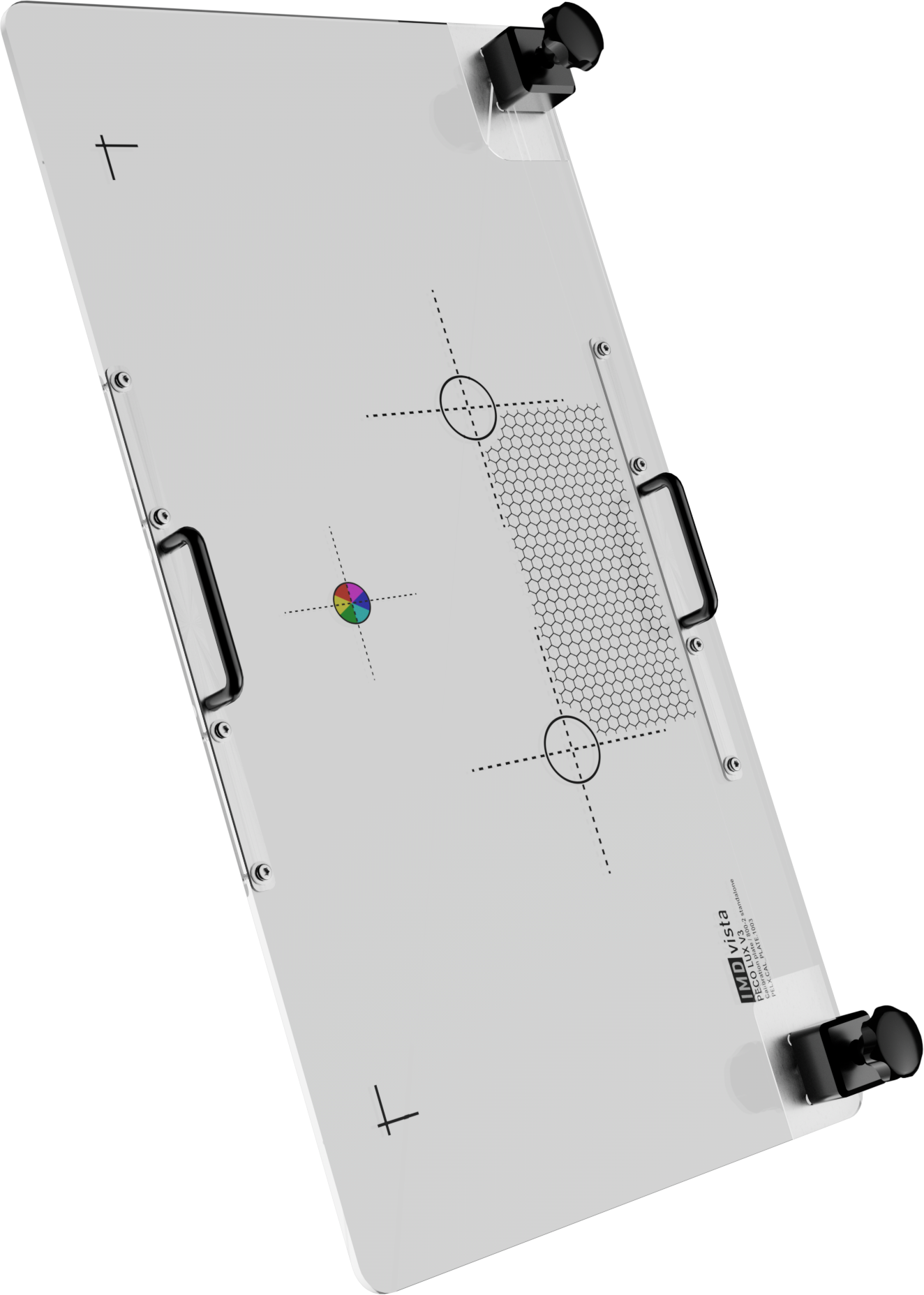

- Fully automated calibration using calibration plate

- Simple, plug and play

- Repeatable and reproductible across all lines and plants

- Ideal for multi-line or multi-site production

- Ensures consistent monitoring performance