- 100% repeatable accuracy for hardware and software

- One MASTER program for all your plants & production lines worldwide

- Same tolerance accuracy on all your CAP MASTER systems

- Same closure quality on all production lines

- Ensures the right settings of all mechanical, optical and camera parameters

- Software and hardware validation

- User-friendly software guidance

- Specific validation tool with official certificate

IMDvista CAP MASTER

First Calibrated and Validated Inline Closure Inspection and Measurement System

The CAP MASTER solution makes it possible to apply consistent quality standards globally, within a single production site or across global manufacturing plants and independent of the experience of local operators.

NEW Calibration & Validation Tool

New absolute Calibrated Measurement and Inspection

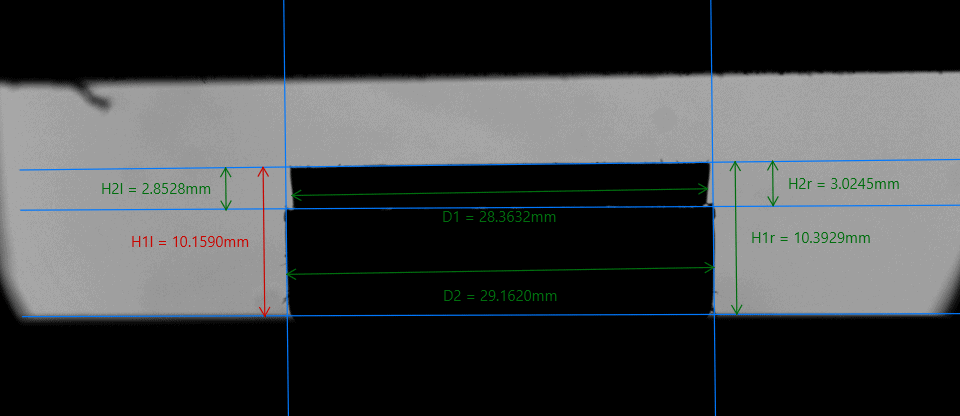

- Measurements: Height, Diameter, Tamper-evident band, Slit position

- Inspection: Inside, 360° outside, Top plate, Print, Cavity, Slit, Bridge, Pinhole

Revolutionary mechanical Backbone

- Base for new calibration process

- Robust and repeatable mechanical setup

- Resistant to external mechanical forces

- Calibrated and documented FAT/SAT

Your competitive advantage

- Same quality standard worldwide on all your CAP MASTER lines thanks to our calibration and validation concept

- Operators require less time for resetting the system after maintenance

- No size parts needed for a wide range of closure designs

- Cost reduction due to minimizes pseudo rejects of non-oriented tethered closures by using artificial intelligence

- Unique precise calibrated inline inspection and measuring system

IMD will be presenting the CAP MASTER at 2 booths at drinktec

- IMD: A5-130

- Sumitomo Demag: C6-160