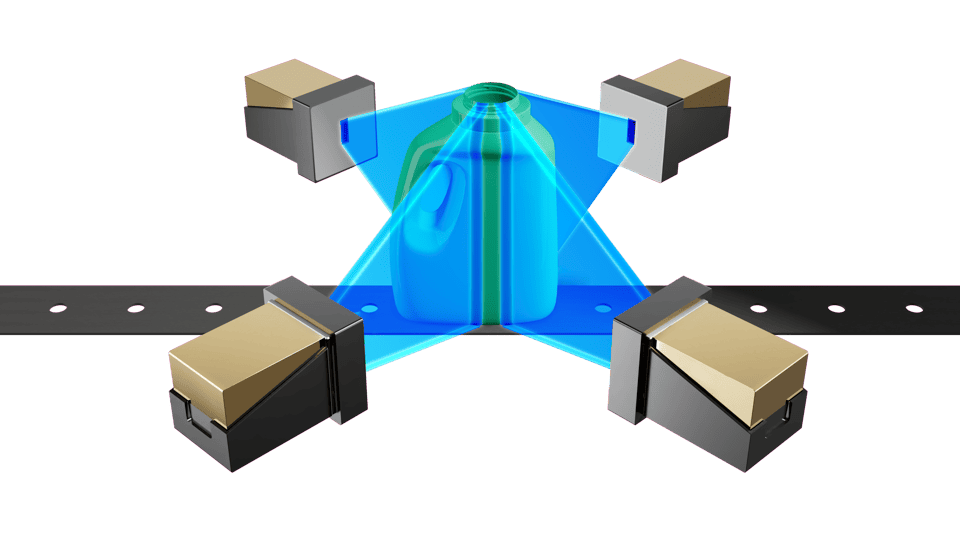

- 360° Bottle Inspection

- The Image is created by scanning the moving bottle

- Over a thousand of line scans per second = 1 image

- Reflection-free

- Camera and illumination positions identical für most bottle designs

- Visibility on edges increased due to consistent view angle

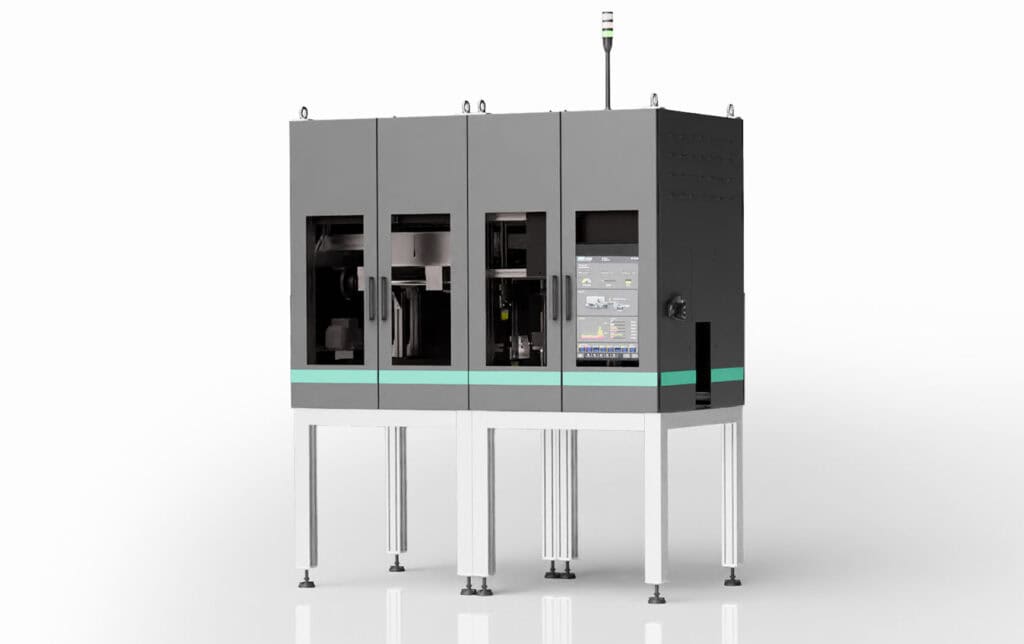

IMDvista BOCO SCAN

New SCAN technology for flexible bottle inspection

IMD BOCO SCAN sets a new standard in bottle inspection technology with its Line Scan Technology. No reflections, same camera and illumination position for all bottle designs and more visibility on the edges. Find out more about the main module and the modularity to Match your Use Case at the IMD booth A5-130 at drinktec.

New Line Scan Technology

Main Module <1 sq.m./<10 sq.ft

This is the compact Bottle Inspection of the whole body with perfect contours. Capable of inspecting opaque and transparent bottles utilizing proprietary illumination and camera techniques.

Body Inspection with Color Line Scan Cameras

- You see deformation, contour, contamination, color streaks, stripes, color variation, indl. Transparent, burnt material, bubbles, scratches, holes

- Optional Neck Inspection Camera

- Optional Inside Neck Inspection Camera

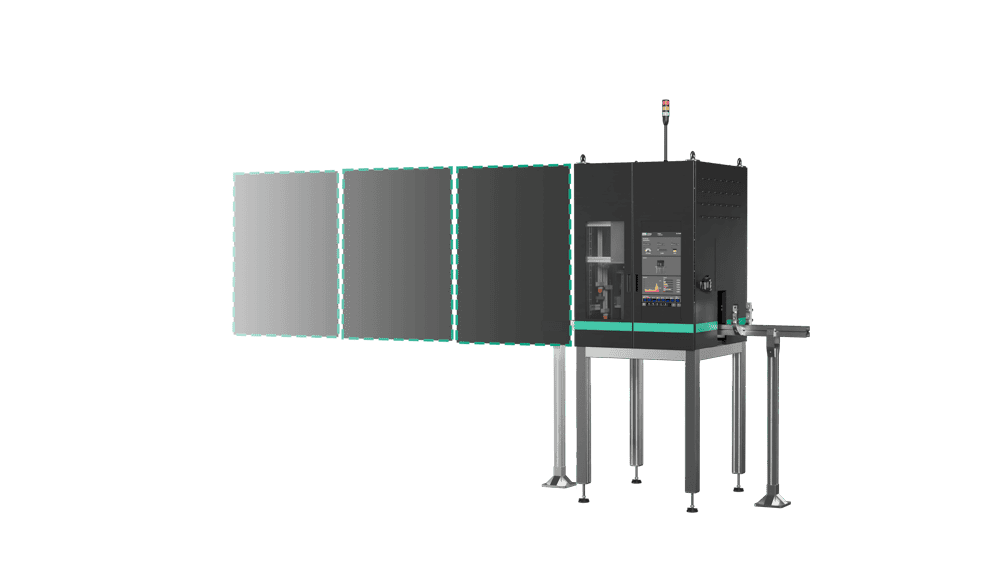

Modular Add-Ons Tailored to your Needs

- Bottom Inspection

- Thin wall / enclosed particles inspection

- Thread inspection

- Precise thread measurement

Your competitive advantage

- Modularity and minimal footprint

- Inspect a wide range of bottle designs

- Fast changeover – no mechanical size parts

- First precise calibrated inline measurement

- Easy and fast integration in your existing production line

IMD will be presenting the IMDvista BOCO SCAN at IMD booth at drinktec

- Main Module and Add-On: A5-130